R&D Library

Compounds are typically formulated with palm kernel oil and usually do not need to be tempered, therefore they are more user-friendly as compared to chocolate. Compounds can be used in a variety of applications including, but not limited to enrobing, molding, panning, and inclusions. Although each coating is different, this fact sheet will explain general recommendations for using, storing, and troubleshooting compounds in applications.

Melting and Application

The usage recommendations for compounds are primarily based on the oil(s) used within the compound. The type of oil (hydrogenated/fractionated) and melt point must be taken in to account. The compound must be fully melted to 10-15°F above, then cooled to 3-5°F above the melting point of the oil in the compound for application use. For example, a coating with a melting point of approximately 95°F should be melted to 105-110°F and applied at 98-100°F.

Cooling

Compounds should then be cooled in a cooling tunnel with temperatures less than 60°F. Compounds made with fractionated oils should be rapidly cooled at the coldest temperature possible, ideally 50-55°F. In contrast, compounds made with hydrogenated oils are more tolerant to wider ranges of temperature and can be cooled at slightly higher temperatures than the melt point range of the hydrogenated compound.

Storage

Because they do not require tempering, molded or enrobed compound products can be more tolerant to temperature fluctuations than chocolate. This tolerance is dependent on the melting profile of the coating, of which the melt point is one indication. However, all compounds should not have prolonged exposure to temperatures over 75°F without risking the appearance of bloom. We recommend that our products are stored at 60 - 70°F and no more than 50 - 60% relative humidity.

Compounds as Inclusions

Compound drops make excellent inclusions and can provide unique flavors and textures to baked goods. There are no special considerations that need to be taken when substituting compound drops for chocolate drops in a recipe. However, due to compounds generally containing more sugar and milk than chocolate products, they can be more susceptible to scorching, particularly in low-water doughs.

Compounds and Water

Compounds, like chocolate, are not compatible with water. Water mixed in with compounds can lead to seizing, where the solids clump together and become unusable. Compounds cannot be ‘thinned out’ with the addition of water because the compound will thicken. Similarly, water-based flavors or colors will cause thickening. Dry cleaning or thorough flushing with oil after wet cleaning is recommended for equipment where compounds are used.

Fat Incompatibility

When different fats are mixed (such as palm kernel oil and cocoa butter) it can cause issues, such as softening and bloom. Care must be taken in formulating products where different types of fats will be interacting to avoid shelf-life issues. For example, a peanut butter candy center may require a thicker compound layer when enrobing as compared to a peppermint fondant center.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

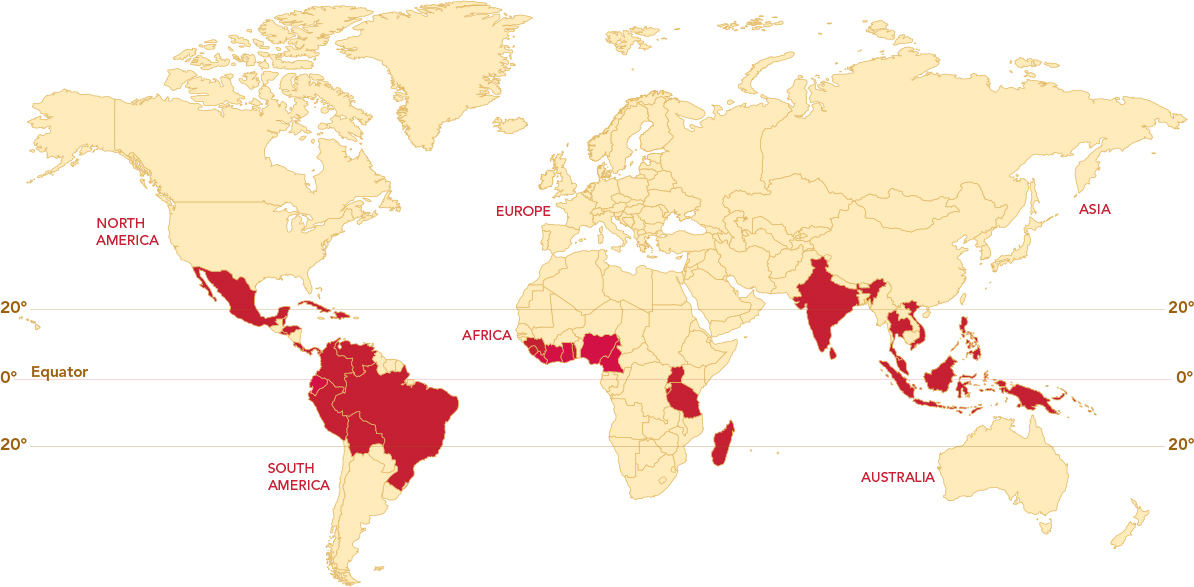

Cocoa beans are typically grown within 20 degrees of the equator. It takes about 2-3 years for the tree to start bearing cocoa pods and about 6-7 years for a full yield. The plant will continue to produce cocoa pods for about 100 years.

AFRICA

West Africa is the largest producing area of cocoa beans, growing approximately 70% of the world’s supply.

Ivory Coast

The Ivory Coast region of West Africa is the largest producer of this region. These beans tend to be high yielding and fully fermented to produce a consistent and balanced chocolate flavor. The beans from this region are typically used as a single origin or as part of a formulation blend with other bean origins in most of the chocolate produced in the world.

Ghana

Ghana beans also deliver a very balanced chocolate flavor and are known for the high cocoa butter yield. The color of the resulting chocolate liquor is usually slightly lighter with a more yellow or orange hue than liquor made from beans from the Ivory Coast.

Cameroon

Cameroon beans have a reputation for hammy, smokey notes combined with the chocolate notes.

Madagascar

This island off the southeast coast of Africa can produce some very special light-colored beans with unique flavors like sour, sharp cheese and sometimes slightly smokey. Madagascar cocoa beans are well sought after due to their unique characteristics.

SOUTH AMERICA

Ecuador

The Ecuadorian cacao tends to be very flavorful with desired notes of brown fruit (such as raisins or figs) and red wine. Ecuadorian beans tend to produce darker chocolate than West African beans and may impart an almost purple hue to the finished product. Beans from this origin are very desirable in dark chocolate and can be part of sophisticated milk chocolate formulas.

Venezuela

Cocoa beans from different regions of this country can produce very distinctive flavors. Overall, flavors can range from sour, rich tobacco to brown fruit, and may at times include woodsy, forest floor notes.

Peruvian

Peruvian beans are known for the slightly acidic, robust fruit notes such as citrus with some fresh raisin or brown fruit notes such as prunes. Most Peruvian cocoa beans are organically produced.

CARIBBEAN

Dominican Republic

DR beans come in two distinct types – fermented (Hispaniola) and unfermented (Sanchez)

Sanchez beans tend to have low chocolate impact due to minimal fermentations.

Hispaniola beans are highly coveted for producing brown fruit (raisin or prune) and rich tobacco notes which may also include some acidity much like the flavor of a tart cherry. Hispaniola beans are excellent complimentary flavors for dark chocolate formulations.

Haitian

Haitian beans tend to have low chocolate impact due to the limited fermentation.

INDONESIA

Papua New Guinea

PNG beans tend to be over fermented, producing over ripe fruit notes that may be described as “smoky”. These beans tend to be very pungent with sour, almost vinegar notes and can range all the way to ashy notes. Papua New Guinea beans have a very distinctive flavor that can be part of a bean blend that produces a high intensity impact in chocolates.

Sulawesi and Sumatra

Indonesian beans from these regions tend to have little fermentation and therefore are not known for delivering high levels of chocolate flavor. The cut test of the beans often reveals a “slatey” or light to dark ash colored interior appearance which indicates low fermentation and can produce a somewhat grey hue when made into chocolate liquor.

Java

Java A grade beans are very special in their very light, pale-yellow hue. The flavor of these beans is unique with some slightly acidic sour notes and an almost sharp cheddar cheese note that can be accompanied by hammy, smokey notes. This bean is highly sought after for producing some very light chocolates that appeal to a very targeted demographic.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

On the farm

Where does chocolate come from? The chocolate process begins with a bean – more specifically a cocoa bean from the Theobroma cacao tree which grows 20 degrees north and south from the equator. Blommer sources the highest quality cocoa beans from most of the cocoa producing countries of the world. A cocoa tree takes approximately 5-7 years for cocoa pods to grow to and these ripe pods each contain about 20-50 beans which are coated in a white plant material called mucilage. Cocoa pods are harvested by hand twice a year, and after harvest, they are left for a few days to cure before being manually split open.

Once the wet beans are removed from the pods they are placed in piles or boxes to ferment. Fermentation is a very important step in turning cocoa beans into chocolate. Over several days, naturally present bacteria and yeasts convert the fruit sugars into ethanol and break down the pulp surrounding the beans, which are then mixed and aerated to encourage more fermentation. The heat that is created in this process kills the bean so it cannot germinate and allows for enzymatic reactions necessary for flavor and color development1.

Next, the beans are dried by being spread out in the sun to reduce moisture content so that the beans can be safely transported without spoiling. Alternatives to solar drying are wood fires or machine drying, depending on the resources of the farm in the country of origin. The dried beans are bagged or shipped loose and then put onto the storage holds of ships to transport to chocolate producing manufacturers all over the world.

In the factory

In the factory, beans are cleaned to remove foreign material, and then they are roasted. The roasting process accomplishes two major objectives: safety and further processing. The beans are safe to eat because the high heat kills harmful bacteria on the beans’ exterior. Additionally, more moisture is driven off, the bean color darkens, and finally, roasting continues the complex flavor development.

Once they are roasted, the beans are winnowed. “Winnowing” refers to the process in which the beans are cracked, and the inedible thin shell on the bean is removed, leaving only the edible portion, also known as a nib. The next step is grinding the nibs into chocolate liquor also known as unsweetened chocolate. Grinding releases the fat naturally present in the cocoa beans, most commonly known as cocoa butter. The heat and friction generated in this process thins out the cocoa solids with the hot liquid cocoa butter.

At this point, we can process the chocolate liquor several ways. The first option is called pressing. Pressing separates the cocoa butter from the cocoa solids in the form of a hard solid cake yielding approximately equal portions of cocoa cake and cocoa butter. The pressed cocoa butter can then be used as in ingredient in the chocolate making process later to alter the viscosity of the product. Cocoa powder is made from grinding the resulting cake, which contains about 10-12% fat and is used in many applications, including but not limited to beverages, bakery items, and compound coatings. White chocolate does not contain any chocolate liquor or cocoa powder, but it does contain cocoa butter, combined with milk, sugar, vanilla, and lecithin (an emulsifier).

After the liquor has been ground, it is combined with sugar and milk powder (for milk chocolates). This paste is refined by reducing the particle size into smaller uniform pieces measured in microns or ten thousandths of an inch. These small particles, also known as “fines” are mixed with some cocoa butter in a vessel called a conche. The chocolate mass is kept warm and mixed or kneaded for several hours. This process is called “conching” and is an important step in improving the eating quality of chocolate because it allows off-flavors to be released. Conching also distributes the cocoa butter evenly between the particles, which gives the chocolate a smoother, creamier mouthfeel. After conching, additional cocoa butter is added with lecithin (an emulsifier) and vanilla or other flavorings to “standardize” the chocolate to a specific viscosity based on its application.

At this point, the chocolate is tempered. Tempering means heating and cooling the chocolate to specific temperatures to promote ideal crystal formation. This is essential so that once the chocolate is formed and solidified, it is has a smooth texture and shiny appearance.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

In the USA, chocolate is manufactured by law to a standard of identity, found in the Food and Drug Administration Code of Federal Regulations Title 21 Part 163 (21CFR163). The ingredients and quantities required can be summarized according to the following guidelines where “chocolate liquor” is defined as unsweetened chocolate that does not contain any alcoholic ingredients:

Milk and dark chocolates must contain chocolate liquor and all chocolate including white chocolate is manufactured with cocoa butter. Cocoa butter gives chocolate unique characteristics such as excellent sensory qualities when properly tempered like hardness (snap) and gloss without a grainy dull appearance. Lastly, cocoa butter has a melt point at body temperature which contributes to a smooth and distinct mouthfeel. As part of the CFR, no flavorings mimicking chocolate, dairy, or caramel may be added to any chocolate product.

Compound

If chocolate does not meet the above standard of identity, it cannot be called chocolate and must be referred to as a Compound. Compound, also known as confectionary coating, is a mixture of sugar, vegetable fat, cocoa powder (in the case of chocolate flavored coating), lecithin (an emulsifier), and flavoring. Compounds can also refer to a cocoa butter-based product where ingredients such as a fiber or protein are added.

Compounds are manufactured with different semi-solid vegetable fats which have more customizable melt points compared to cocoa butter used in chocolate. These lower and higher melt points yield functionalities useful in many different applications ranging from “chips or drops” in cookies to the coating on ice cream bars.

Blommer’s compounds are manufactured on equipment following the exact same high-quality safety and manufacturing standards for chocolate. When comparing a chocolate to a compound, it may be difficult to perceive the difference between the two because the sensory qualities are also very similar.

Compounds generally do not require tempering and are more versatile for applications that require different temperatures usages. Also, because there isn’t a standard of identity for compounds, compounds can be fortified, colored, or flavored with so many more possibilities compared to chocolate.

Yogurt Flavored Confectionery Coatings

We offer a variety of yogurt flavored compounds with each formulation developed for a specific application and flavor profile based on market trends. We use various yogurt powders that have unique profiles and contain different ingredients such as cultured nonfat milk powder, whey protein concentrate, yogurt cultures, cultured whey, and lactic acid.

The FDA has a standard of identity for yogurt (21 CFR 131.200, 203 or 206), but not one for yogurt powder. Confectioners have two options to incorporate yogurt into applications. Yogurt powders manufactured from standard of identity yogurt contain live active cultures prior to drying and blending; however, this heating process kills the cultured bacteria in the yogurt. The resulting yogurt powder has comparable nutritional content and tart flavor of non-dried yogurt. Another yogurt alternative is a blend of dairy ingredients not derived from standard of identity cultured yogurt, yet the blend has added yogurt flavor.

Recently, the yogurt industry introduced Greek style yogurt also known as Greek Yogurt. It is characterized as a thicker, creamier yogurt with tart flavor with a higher protein content compared to regular yogurts. Greek yogurt does not currently have an FDA standard of identity. Blommer’s version of Greek yogurt confectionery coating is made with spray dried Greek yogurt powder which provides similar flavor and nutritional content of the non-dried version of Greek yogurt.

Our labeling recommendation for all yogurt coatings is “Yogurt Flavored Confectionery Coating.” Some customers prefer to state that the cultured yogurt is pasteurized (heat treated to eliminate harmful bacteria) and spray dried to emphasize that the beneficial live active cultures are no longer present in the final yogurt confectionery coating.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Blommer has successfully converted higher fat cocoas to standard cocoas in ice cream and bakery formulations. This conversion can be a source of cost savings that will not result in a significantly different flavor profile or texture. The following calculations are a guide for modifying a formula to make the change from high fat to standard (10-12%) cocoas. These calculations are intended for formulas expressed in percentages which total to 100%. This guide is meant to be a starting point where adjustments may be necessary based on your application.

Step 1: With less fat, there is a higher concentration of cocoa solids in standard 10/12 fat cocoa. Therefore, to convert from high fat to standard 10/12 fat cocoas, one must decrease the amount of cocoa accordingly.

- For 15/17 to 10/12: Current % * 0.944 = new cocoa

- For 22/24 to 10/12: Current % * 0.865 = new cocoa %

This is the new percentage of cocoa to be used in the formula. There will always be less cocoa than was previously used.

Step 2: Depending on the recipe, one may also want to increase the fat in the formula. This is suggested for baked goods but increasing the fat may not be necessary depending on the amount of cocoa in the formulation and the other ingredients in the formula. This calculation is the same for 15/17 and 22/24 cocoas:

- Current % cocoa – New % Cocoa = Additional Fat %

- Ex: 7.00-6.61 = 0.39

This additional fat percentage should be added to the fat in the formula (shortening, oil, etc.). If the fat in the formula is butter, for example, proceed to step 3. If not, no further calculations will be needed. Your formula should still add up to 100% and contain more fat and less total cocoa compared to the previous formula containing high-fat cocoa.

Step 3: If the fat system in the formula is butter, and your formula is quite sensitive to changes in fat and moisture, or the amount of cocoa in the formula is quite large, then additional calculations may necessary. Since butter is approximately 80% fat and 15% water, one must increase the total amount of added butter and decrease the water accordingly:

- Additional Fat %/ 0.8 = Additional Butter %

- Ex: 0.39/0.8 = 0.49

This number should be added to the butter in the formula (instead of the value calculated in step 2 above).

- Additional Butter % * 0.15 = Water Decrease

This number should be subtracted from the water percentage in the formula (given that there is water present in the formula).

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Cooling Tunnels

The cooling tunnel and the temperatures used are critical in achieving an ideal appearance for finished products. The settings of the cooling tunnel are dependent on the type of chocolate or compound used. In any application, once chocolates are tempered or compounds are at usage temperature, the remaining heat left in the chocolate or compound must be removed properly to ensure that the product maintains its temper and forms the correct crystal structure.

The crystallization behaviors of cocoa butter and vegetable oils are so different that chocolate and compounds require different temperatures and settings for the cooling tunnel. To promote the growth of stable crystals and prevent bloom, tempered chocolate requires gentle cooling conditions. Cooling chocolate too quickly could produce small holes or tiny cracks on the surface along with unstable crystals, while cooling too slowly can create bloom. Unlike chocolate products, compounds made with fractionated oils need a quick “cold shock” of cold temperatures when entering the cooling tunnel to crystallize into a stable form. Compounds made with hydrogenated oils perform better when cooled at slightly higher temperatures than fractionated oils. Table 1 below shows the ranges of typical suggested temperatures for the different cooling tunnel zones.

There are different types of cooling tunnels, but three-zone ( or more) type tunnels are the most ideal for chocolate and compounds as they allow for more control of optimal cooling conditions and crystal formation. In the first zone of the cooling tunnel, the heat from the finished product escapes with the help of mild air flow. The middle zone requires moderate air flow to further cool and completely solidify the product. The third or last zone (depending on the cooling tunnel) continues to cool the product but increases the temperature above the dew point of the production environment. If the exit temperature of the product is below the dew point of the room, the humidity in the air may condense on the surface of the finished product potentially resulting in moisture marks or sugar bloom.

Table 1: Cooling Tunnel Parameters

| Zone 1 | Zone 2 | zone 3 | |

|---|---|---|---|

| Chocolate | 60-65°F | 45-50°F | 60-65°F |

| Compounds with Fractionated Oil | 40-45°F | 39-43°F | 55-65°F |

| Compounds with Hydrogenated Oil | 50-55°F | 40-45°F | 55-65°F |

Data in this table will vary based on the coating and equipment used, length and air flow of the cooling tunnel.

Storage

The ideal storage conditions for finished products are a dry, odor-free environment away from direct sources of light and approximately 60-70°F (15.5-21°C) with a relative humidity around 50%-60%.

We do not recommend storing chocolate or compounds in the refrigerator or freezer because moisture can develop on the surface and potential odors will affect the coatings negatively. However, if finished products that have been previously stored in the refrigerator or freezer are carefully thawed by gradually increasing to room temperature, condensation may not form on the surface.

If proper storage environment temperatures are not maintained the product could melt and fat bloom (unstable white fat crystals on the surface of chocolate and compounds) may develop. Products not properly stored may have a shortened shelf life, and dry products like cocoa powders could clump and potentially bloom. If a product is not stored with proper relative humidity, moisture on the product could create sugar bloom, and the product could have a shortened shelf life with possibly an increase in viscosity.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Bean to Bar

Types of Chocolate

All chocolates are legally defined in the US FDA CFR Title 21 Part 163.

Chocolate and Compound Production

Tempering

Viscosity

Applications

Cocoa

Antioxidants

Certifications

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Emulsifiers have been widely used in the chocolate and compound industry for decades to change flow properties, to lower or maintain the viscosity, to improve functionality and keep costs lower. In the US, the standard of identity for chocolate products states that total emulsifiers must be kept below 1% of the formula. A chocolate can be made without emulsifiers, but the cost would be higher since it takes approximately 7-10% more cocoa butter in the formula depending on the desired viscosity.

As with many ingredients, emulsifies have optimal usage rates. Using too little can leave the chocolate or compound “unstable” which can lead to viscosity instability or moisture absorption. Using too much can lead to a significant increase in viscosity and off flavors.

Emulsifier Types and Amounts

- Lecithin – Lecithin is the most common emulsifier in chocolate and compound manufacturing. It is typically made from soybeans but versions using sunflower, and safflower exist as well. Lecithin can significantly reduce the product viscosity, particularly plastic viscosity, by adding little cost.

- PGPR – PGPR stands for polyglycerol polyricinoleate and is made from castor beans. PGPR can reduce the viscosity of chocolate, particularly yield value, while also adding little cost. PGPR is often used in conjunction with lecithin for optimum viscosity reduction as it does not function well as a sole emulsifier.

- AMP – AMP, or Ammonium Phosphatide, is common in European confections, is made from rapeseed oil and can also be used in conjunction with lecithin or by itself. The FDA declares that AMP may be used at a rate up to 0.7% in chocolates. This may also be labeled as “Emulsifier YN” on labels.

Additional Emulsifier Additives in Chocolate

- Sorbitan Tristearate – This can be used in chocolate, and categories as an emulsifier, if it is kept under the 1% total emulsifier amount. Sorbitan tristearate can be used to help delay the effects of bloom. This can be used as a bloom inhibitor in compounds at a higher rate to help delay bloom and hasten the hardening period of compounds.

- Distilled Monoglycerides – This can be used in a similar fashion to sorbitan tristearate. If it is kept under 1% total emulsifier, the chocolate may be labeled as “Chocolate” according to the US FDA CFR standard of identity for chocolate. This can also be used to help inhibit bloom in chocolate and compounds.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

FAT BLOOM IN CHOCOLATE

What is Fat Bloom?

Fat bloom is characterized by a dull white or gray layer of fat that appears on the outer surface of solid chocolate and when touched, the surface feels greasy. Although this appearance is unappealing, the chocolate is safe to eat. Fat bloom impacts flavor and textural qualities of chocolate such as softening and/or crumbled and a granular mouthfeel. This texture negatively impacts the shelf life of finished products made with chocolate.

What Causes Fat Bloom?

Fat bloom can be caused by the incorrect chocolate usage temperatures or improper tempering techniques such as uncontrolled heating and cooling of melted chocolate. Other potential causes of fat bloom are related to improper temperatures in cooling tunnels, storage, or shipping. Even dirty product molds and equipment used during chocolate application, or excessive manual handling of the finished chocolate can cause fat bloom. Confectionery centers may also be a cause of fat bloom because they may not be at the appropriate temperature or contain a fat incompatible with cocoa butter.

How to Prevent Fat Bloom in Your Product

Blommer recommends using a proper tempering protocol. (Learn more about tempering here.) Fat bloom prevention is dependent on understanding finished product formulation, ingredient interactions, ideal temperature application parameters, and proper handling and storage of finished products.

SUGAR BLOOM IN CHOCOLATE

What is Sugar Bloom?

Sugar bloom is caused when the surface of the chocolate is exposed to excess moisture that dissolves the sugar in the chocolate. This sugar recrystallizes on the surface of the chocolate leaving a white/grey or spotted appearance. When touched with the finger, the surface of the chocolate feels grainy and dry (i.e. sandy texture).

What Causes Sugar Bloom?

Sugar bloom is caused when chocolate is stored in damp conditions, high relative humidity (%RH), or there are large fluctuations in storage resulting in condensation on the surface.

How to Prevent Sugar Bloom in Your Facility

Sugar bloom prevention entails several parameters: understanding dew point in the processing lines, regulating temperature differentials in storage conditions, and controlling relative humidity.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Ganache is an emulsion of chocolate with liquid, traditionally cream. It may include additional ingredients which provide additional functionality such as mouthfeel (butter), shelf life (corn syrup, glucose, etc.), or flavorings (liqueurs, puree, or infusions). Less common forms of ganache may include egg ganache, butter ganache, and water ganache.

Ganache is traditionally made by bringing cream with any sugar ingredients (corn syrup, etc.) to a boil, pouring it over finely chopped chocolate, and then emulsifying the mixture with a whisk or immersion blender, being careful not to incorporate air. It can also be made by warming cream and mixing the cream with melted, tempered chocolate. The ganache made from tempered chocolate will set more quickly than the boiled cream method.

By varying the ratio of chocolate to liquid, one can create a ganache that is firmer or softer, depending on the application. Applications for ganache range from sauce (softer) to hand rolled truffles (firmer). The perfect ratio will depend upon the chocolate you are using and the desired finished texture of your application.

Suggested starting ratios for ganache with heavy cream:

| Type of Ganache | Type of Chocolate | Cream to Chocolate Ratio |

|---|---|---|

| Soft ganache (sauce, cake coating, moulded truffles) |

Dark | 1:1 |

| Milk & White | 1:1.5 | |

| Firm Ganache(hand rolled truffles) | Dark | 1:2 |

| Milk & White | 1:2.5 |

While not ideal, compounds can be used to create ganache as well. One will need to experiment to determine exact ratios of coating to cream for the desired application, as it will differ based upon the coating being used. Generally, the compound-based ganache will require less cream and may result in a stickier finished texture than one would expect from a chocolate-based ganache.

Due to a high proportion of water activity, the shelf life of true ganache is short (approximately two weeks if properly made & stored). An alternative to a true ganache is to soften chocolate or compound with a small proportion of a more liquid oil, such as coconut oil or soybean oil. This works particularly well for cake or bar toppings which need to be soft enough to slice without being sticky.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Kosher is a Hebrew word that means “proper or pure,” and Kosher foods are formally allowed for Jewish people to eat as stated in the Torah1, the body of wisdom and law contained in Jewish Scripture and other sacred literature and oral tradition. A certified Kosher product is allowed to be consumed or used according to dietary and ceremonial laws and certified by a Rabbinical Council. Each Rabbinical Council has their own certification symbol as shown below. At Blommer Chocolate, each plant location uses different Rabbinical Councils to certify that products are Kosher. Because of this, not all products will show the same symbol on the label.

Examples of Rabbinical Councils and their symbols:

- Organized Kashrus Laboratories

- Chicago Rabbinical Council

Kosher Dairy

Milk products can be labeled Kosher if they are produced from Kosher animals. The label will show a capital letter ‘D’ after the Kosher symbol to designate a product that is Kosher dairy. This designation means the product contains a dairy ingredient, a dairy derivative, or was made on equipment also used for making dairy products. Please note that some of Blommer’s dark chocolates without milk are Kosher Dairy because they are produced on a line shared with milk containing products. Please consult customer service or your sales representative for Kosher guidance regarding your specific product and projects.

Pareve

Pareve foods contain neither meat, dairy, or dairy derivatives, and therefore, Pareve foods are permissible to be eaten with both meat and dairy dishes according to dietary law. Pareve products are not processed with heat on equipment that has processed dairy containing foods. For example, all fruits, grains, vegetables, water, and minerals in their natural state are all considered Pareve. This is a designation for religious reasons and does not necessarily mean dairy allergens are not present.

All Pareve products made are required to have a flush procedure prior to product manufacture. These products also generally have designated equipment that is separate from equipment that processes products with dairy but may be processed through shared pipelines with dairy ingredients.

Passover

Passover chocolates are a special level of Kosher certification. Blommer Chocolate no longer produces Kosher for Passover products.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Protein

Proteins are the building block of life and proteins are needed by every cell, tissue, and organ because are used to help your body repair and make new cells. Proteins consist of one or more polypeptides, a single linear polymer chain of amino acids (organic compounds made of carbon, hydrogen, oxygen, and nitrogen) bonded by peptide bonds. There are 20 types of amino acids that make up these polypeptides, and most living organisms and plants can make these amino acids whereas animals like humans are unable to synthesize certain amino acids and must obtain them through diet. Those that can’t be made by our body are called essential amino acids. A protein source that contains all the amino acids are called complete proteins. Our body will digest the protein into the amino acids to produce energy, build more proteins, and support bodily functions.

There are 2 main categories for proteins - Animal based (beef, pork, chicken, milk, eggs, fish) and plant based (beans or legumes, cereals, nuts, and seeds).

Functionality of Protein in Chocolate

Most people are not aware that cocoa beans contain small amounts of protein however, the main sources of proteins in our chocolate and compound coatings are from milk such as whole milk, nonfat milk, and whey powders. Fortified dairy ingredients include Whey Protein Concentrate (WPC), Whey Protein Isolate (WPI), Whey Protein Hydrolysate, Milk Protein Isolate (MPI), and Sodium/Calcium Caseinates. Soy Protein Isolate (SPI) is a plant based option that also works well in confectionery products. These complete proteins not only add to overall nutrition content, but they also impact texture, flavor, and the rheological properties (viscosity) of finished chocolate products.

Blommer is continuously researching alternative proteins to provide improved nutritional advantages in health and wellness and to offer more sustainable, plant based lifestyle choices. Furthermore, extensive testing has gone into enhancing functionality in sugar free and no sugar added chocolate or compound coatings with added proteins. Blommer continues to lead the industry with our Better-For-You products, including protein fortified coatings.

Nutritional Discussion

Proteins are categorized by how many essential amino acids they contain. Complete proteins have all essential amino acids. Animal based proteins are complete proteins. Incomplete proteins are deficient in one or more essential amino acids.

Proteins are given PDCAAS scores (Protein Digestibility Corrected Amino Acid Score), which indicates the overall quality of a protein based on amino acids present as well as human digestibility. The scale is from 0-1, with 1 being the highest, which means the protein has all essential amino acids and is highly digestible.

Current Trend

From a functional food perspective, protein fortified products continue to be one of the most popular consumer trends. The main consumers of protein fortified products have shifted from sports related to health-conscious consumers and more mainstream consumers desiring weight management, satiety, and daily consumption of protein as an integral part of a well-balanced diet.

Within the nutritional bar and confectionery industry, WPC is considered the gold standard among proteins. Plant-based proteins are trending but can be challenging due to pricing, availability, flavor, and functionality in confectionery products. Plant protein sources will continue to increase in demand if consumers desire more sustainable alternatives to animal sources of protein.

Blommer Items

Blommer Chocolate offers a variety of products fortified with milk proteins. Most of these products are whey protein concentrates based, but others include milk protein isolates.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Consuming a diet of foods containing trans fats sourced from partially hydrogenated oils and saturated fats contributes to increased risk of developing heart, stroke, or Type 2 diabetes. According to the Centers for Disease Control and Prevention (CDC), heart disease is the leading cause of death in the US. In 2006, food manufacturers were required to label trans-fat on packaged foods Nutrition Facts labels1.

In 2015, the US Food and Drug Administration (FDA) ruled that trans fats were no longer Generally Recognized as Safe (GRAS) and deemed unsafe, and by June 18, 2018, food manufacturers needed to remove artificial trans fats2. The food label compliance date was extended to January 1, 2020, for non-petitioned use partially hydrogenated oils, and January 1, 2021 for companies who petitioned for partially hydrogenated oils usage3. Most partially hydrogenated oils have been eliminated from foods, but manufacturers have exemptions such as for naturally occurring trans fats and current FDA regulations4.

Here are several important definitions:

Fatty Acids are the main components of fat that are important for diet and bodily functions. Fatty acids are various lengths of carbon chains that are either bent (unsaturated) or straight shaped (saturated).

Saturated fat is a fatty acid that has a hydrogen atom attached to every carbon atom by a single bond, making it fully saturated with hydrogen atoms. The full saturation of the hydrogen atom makes it more stable, prolonging the shelf life. Saturated fat is found in several common food products such as hard cheese, cream, meat products, palm oil, and palm kernel oil. High intakes of saturated fat have been shown to increase the low density lipoprotein cholesterol (LDL-C) also known as the “bad” cholesterol. Increased levels of the “bad” cholesterol increase ones risk for heart disease.

Trans fatty acids, also known as trans fat, can be artificially made by the controlled addition of hydrogen gas in the presence of a known amount of chemical catalyst to liquid or semi-liquid vegetable oils thus producing a more shelf stable, solid vegetable fat. The additional hydrogen creates a more rigid fat structure. During the partial hydrogenation process the fat chain changes so that the hydrogen atoms are on different sides of the carbon chain as opposed to being on the same side. This chemical orientation is where the nomenclature “trans” is derived from. Trans fat is also found naturally in the meat and dairy from ruminant animals (herbivore mammals who twice digest plants or cud). Like saturated fat, high dietary intake levels of artificial trans fat also increase heart disease by increasing bad cholesterol Scientists have yet to determine whether consuming small amounts of naturally occurring trans fat negatively affects cholesterol like consuming artificial trans fats5.

US food manufacturers now source alternatives to partially hydrogenated fat from vegetable fats that are semi-solid and solid such as fractionated (carefully selected solid fractions) or fully hydrogenated (no trans fat) or interesterified (rearranged fatty acids) palm, palm kernel and coconut oils. Generally, “fats” are solid and “oils” are liquid at room temperature.

These fats and oils are used to make the desired characteristics of compound and chocolate confectionery products such as coatings and drops. In compounds, palm kernel oil (fractionated and fully hydrogenated), palm oil, soybean oil, and coconut oil are commonly used whereas, chocolate is made with cocoa butter and milk fat. Cocoa butter contains very little trans fat and the portion of saturated fat, derived from stearic acid, has been shown to have minimal detrimental health effects when compared to other saturated fats. Table 1 shows the typical amounts of trans and saturated fat found in chocolate and compound coatings.

Table 1: Approximate Range of Trans and Saturated Fat in Oils

(Based on 100 Gram Serving Size)

| OIL TYPE | TRANS FAT (grams) | SATURATED FAT (grams) |

|---|---|---|

| Cocoa Butter | 0.1 | 59.3 – 59.90 |

| Milk Fat (Butter Oil) | 3.0 - 6.67 | 60.2 - 67 |

| Fractionated Palm Kernel Oil | 0.1 | 86.8 – 92.90 |

| Hydrogenated Palm Kernel Oil | 0.4 – 2.0 | 94.7 - 98.5 |

| Partially Hydrogenated Palm Kernel Oil | 0.4 - 1.7 | 93.9 |

| Palm Oil | < 1.0 | 45.98 - 87.25 |

| Coconut Oil | < 0.2 – 0.4 | 91.2 – 99.1 |

| Soybean | 0.5 - 1.5 | 14 - 15 |

Source: These figures were generated from current oil supplier nutritional data. The figures used will vary based on the oil and oil supplier being evaluated.

According to current FDA regulations, if the trans-fat for a product is under 0.5% and there are no fats, fatty acids or cholesterol content claims, it does not have to be declared with a footnote stating, “Not a significant source of trans fat,” or it can be listed as 0 grams trans-fat per serving6. Chocolates and Compounds do contain saturated and trans-fat, however the levels of these fats tend to be so minimal that most coatings fall under the 0.5% ruling. Because trans-fat is naturally occurring in dairy products, it is virtually impossible for a chocolate or compound to contain 0 trans-fat. Table 2 shows the breakdown of trans and saturated fat in standard chocolates and compounds. Although the data listed in Table 2 is not representative of every coating, all the coatings included in Table 2 have less than 0.5% trans-fat.

Table 2: Approximate Range of Trans and Saturated Fat in Chocolates and Compounds

(Based on 100 Gram Serving Size)

| TRANS FAT (grams) |

SATURATED FAT (grams) |

|

|---|---|---|

| White Chocolate | 0.20 – 0.46 | 17.64 - 22.41 |

| Milk Chocolate | 0.26 - 0.32 | 21.27 – 21.45 |

| Dark Chocolate | 0.03 – 0.17 | 16.62 – 22.97 |

| Compound Coating with Fractionated Palm Kernel Oil | 0.03 – 0.15 | 25.91 – 31.49 |

| Compound Coating with Partially Hydrogenated Palm Kernel Oil | 0.46 – 0.50 | 25.21 – 30.78 |

| Ice Cream Coating with Coconut Oil | 0.01 – 0.03 | 41.99 - 51.36 |

| Ice Cream Coating with Coconut and Soybean Oil | 0.08 - 0.12 | 43.58 – 49.20 |

Source: These figures were generated from current products produced by the Blommer Chocolate Company. The figures will vary based on the specific product being evaluated.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

1https://www.washingtonpost.com/news/wonk/wp/2018/06/18/artificial-trans-fats-widely-linked-to-heart-disease-are-officially-banned/

2https://www.cdc.gov/nchs/fastats/leading-causes-of-death.htm

3https://www.fda.gov/food/cfsan-constituent-updates/fda-extends-compliance-date-certain-uses-partially-hydrogenated-oils-food-denies-petition-certain

4 https://www.washingtonpost.com/news/wonk/wp/2018/06/18/artificial-trans-fats-widely-linked-to-heart-disease-are-officially-banned/

5https://www.heart.org/en/healthy-living/healthy-eating/eat-smart/fats/trans-fat

6https://naldc.nal.usda.gov/download/1759360/PDF

The tempering of chocolate can be defined as the controlled temperature process used with melted chocolate to select the ideal type and size of cocoa butter crystals. The result of a well-tempered chocolate is hardness (snap), texture, and contraction or release from a mold. Poorly tempered chocolate may form a white or gray fatty substance called fat bloom due to the less stable crystalized cocoa butter on the surface of the chocolate. Not only is fat bloom an indicator of poor temper, but the chocolate could also have other undesirable characteristics: lack of shine, poor flavor release, texture issues (soft, granular, melts quickly when handled, does not contract) and a shorter shelf life.

Mastering the ideal chocolate temper is an art – Blommer understands that tempering encompasses both technique and science. This information should be used as a guide for tempering chocolate, and please note each formulation is different and every process and application is unique. Therefore, we recommend determining specific parameters for each product, process environment and application.

Triglycerides

Cocoa Butter is comprised of various triglycerides, but mainly they are stearic-oleic-stearic (SOS), stearic-oleic-palmitic (SOP) and palmitic-oleic-palmitic (POP). Composition varies based on growing location with origins closer to the equator contain higher levels of saturated fat which will lead to harder cocoa butter.

The most important aspect of tempering is to guide the triglycerides into the most stable crystalline structure. In total, there are six different crystal structures and we are mainly concerned with alpha, beta prime and beta crystal forms. Each crystalline form is created at different temperatures, and the formation of beta crystals is most desired below its melt point of about 93° F (33.8°C). Beta crystals create tightly packed building blocks producing a more stable, solid chocolate which contracts well after cooling and yields an ideal texture such that it snaps when cut or eaten. Additionally, the quantity and size of the crystals is very important. Too many crystals can result in product that is over-tempered and dull in color and appearance. Under-tempered chocolate lacks an adequate quantity of stable crystals, and it may take too long to solidify or the chocolate fails to set up completely.

There are many ways to temper chocolate, but the goal is always the same – to select for the beta crystals, in the most ideal size and quantity. The following will describe different methods to temper chocolate. It’s important to note that white and milk chocolates typically have higher levels of milkfat which contributes to the overall fat matrix and depresses the melt point of the chocolate. White chocolate contains cocoa butter and typically relatively high amounts of milk fat and solids, thus we recommend cooling and reheating white chocolate lower than milk chocolate. We recommend cooling and reheating milk chocolates 1.0-2.0° F lower than dark chocolates to compensate for this difference. Milkfat has relatively lower melt point 19.5° C (67° F) compared to cocoa butter 30-35° C (86-95° F) thus, milkfat is usually liquid at room temperature.

Seed or Chunk Method

The Seed or Chunk Method needs the following equipment: a melter with agitation and temperature controls, a handheld thermometer or infrared (IR) temperature gun plus a heat stable flexible silicon or plastic spatula. Without a melter, an acceptable substitute is a heat proof bowl in a water bath or a double boiler with stove or a portable burner on low temperatures. Note that it is important to avoid mixing water into the chocolate from the double boiler or the cooling process when using a bowl and mixing by hand. If water is accidently added into chocolate, it is best to discard that mixture due to seizing and potential bacterial issues. We do not recommend using a microwave on low power settings in lieu of a stove or portable burner for melting large quantities of chocolate because the heat distribution is difficult to control.

- Chop or break well-tempered chocolate into small chunks and place into the empty mixer. This is known as the “seed” which is initiating the proper cocoa butter crystal structure for the chocolate mass. The seed quantity should be approximately 5-10% of the total amount of chocolate one is tempering.

- Turn on the heating element and agitator on the melter. Allow the mass to melt completely and mix while checking the temperature of the chocolate frequently until it reaches 46-49° C (115- 120° F). If using a bowl or double boiler, melt the mass completely in the same way described for the melter.

- Once completely melted, continue to agitate, or stir the mass and turn off the heater on the unit and remove from the heat. Start adding chunks of well tempered seed chocolate into the melted chocolate. Stir the chunks into the chocolate until the temperature reaches about 29.0-31.5° C (84-89° F) for Dark Chocolate, 27.0-31.0° C (81-88 °F) for Milk Chocolate, and 26.0-30.0° C (79 -86 °F) for White Chocolate.

- At this point you can apply the chocolate in the desired application.

Automated Tempering Method

Another common method is the Automated Tempering Method. Most industrial users of chocolate incorporate use of tempering machines that continuously temper chocolate without additional tempered blocks of chocolate. This can also be done without an automatic tempering unit. The only difference in the equipment needed above is that the melter (or bowl) will need to be heated as well as cooled with constant mixing.

- Heat and agitate the mass of chocolate to 46.0-49.0° C (115- 120° F). See Temperature 1 on Table 1.

- Rapidly cool the chocolate to recommended temperatures in Temperature 2 on Table 1. Continue to agitate during the process.

- Reheat the chocolate to Temperature 3 on Table 1.

- At this point you can apply the chocolate in the desired application. It’s recommended not to coat products that are above 21.0° C (70° F) due to risk of detempering the chocolate or below 10.0° C (50° F) due to rapid hardening of the chocolate

Cooling the Chocolate

Cooling of the finished chocolate products is another important aspect in the tempering process. decrease the chocolate temperature gradually to prevent shocking the chocolate or cooling too quickly. Shocking can select and grow the wrong cocoa butter crystals, and the finished chocolate will not have the same ideal tempered characteristics as stated above. Most industrial systems incorporate a cooling tunnel which gradually cools the chocolate through controlled humidity and temperature zones.

The beginning of the cooling tunnel should have low air velocity on the product and temperatures in the range of 15.5-18.5° C (60-65° F). The second zone or middle of the tunnel will typically be in the 4.5-7.0° C (40-45° F) temperature range with more air being blown on the product. Finally, the third zone or end of the tunnel should be higher 18.5-20.0° C (65-68° F) to prevent condensation or a layer of moisture on the surface of the finished product.

Another important variable to consider for ideal chocolate temper is the dwell time of the product in the cooling process. The amount of required cooling time is determined by the quantity and size of the finished chocolate being cooled where generally smaller, thinner pieces need shorter time to solidify and larger, thicker pieces will need more time to cool to completely remove the heat from the center of the product interior. Dwell time may typically range between 10-30 minutes depending on the speed, size (length and width) of the cooling tunnel. Finally, chocolate may need 24 to 48 hours to full solidify with stable cocoa butter crystals with consideration of other external influences like the product packaging and storage environment 15.5 - 21.0° C ( 60 - 70° F) temperature range, 50%-60% relative humidity, and lack of direct heat or light sources from other equipment.

Temper Meter

Temper Meters are an excellent tool for confectioners. This device allows you to know the “degree of temper” of your chocolate by measuring the rate of fat crystal formation in the form of slope. A result slope of 0 is the target meaning your chocolate has perfect temper. A negative slope indicates that your chocolate is over tempered and has an excess of crystal formation. To correct this, a confectioner can increase tempering temperatures slightly. A positive slope indicates that your chocolate is under tempered and has a lack of crystal formation. To correct this, a confectioner can decrease tempering temperatures slightly.

Tempering liquid chocolate is an important and necessary process for ideal chocolate appearance, texture, and flavor. No matter which method used, a successfully well-tempered chocolate will be shiny and hard, showcasing the best sensory properties a chocolate and finished confection can have. With our expertise of the science and skills needed to temper chocolate, we collaborate with our customers to better help them tailor their chocolate for their applications and production process especially trouble shooting when necessary. Most importantly, our customers will have the knowledge and the highest quality chocolate to make the finest confections in the industry.

For a video of a chocolate tempering method, please click here.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

Cocoa powder is the ingredient of choice for introducing chocolate flavor into a variety of foods. Natural cocoa powder provides mild, cocoa notes and a relatively light color. Through the alkalization process, a spectrum of brown to red shades and flavor profiles are created. Each unique alkalized cocoa has a particular color, flavor, and pH, and may behave differently based on the other ingredients in the final product. Therefore, when selecting a cocoa powder, it is best to discuss project objectives and final applications.

pH: pH is generally a crucial parameter for performance. Cocoas within the same pH range can vary greatly in color & flavor.

- Higher pH cocoa powders can interfere with chemical leavening ingredients during baking, resulting in large air bubbles. This produces “tunneling” or “overspreading” in cookies.

- High free alkali (generally of concern with very heavily alkalized cocoas such as Jet Black) can prevent gelling or thickening in products like pudding or custard. Free alkali may reduce the stability of proteins and reduce shelf life.

Color: Cocoa color should always be compared and evaluated in the final application, and never as dry cocoa. The color of cocoa powder is dependent on age, temperature, and hydration level, as well as the pH of the final application.

- Warmer cocoa powder = darker (due to melting of cocoa butter)

- Wetter cocoa powder = darker (due to hydration)

- In application, high pH ingredients (leavening agents, baking soda) darken color, particularly of natural cocoa.

Typical Flavors and Applications for Various Cocoas:

| Color Range | Cocoa Powders | Typical flavor | Common Applications |

|---|---|---|---|

| Lightest (non-alkalized) |

Natural (NI) | Mild, cocoa-y notes and slight acidity | Compounds, syrups |

| Light | Mojave, Sequoia, Horizon, Sudan | Cocoa-y notes with mild alkali undertones | Spreads, pudding |

| Medium | Sunset, Teton, Zion, Bandelier | Moderate alkalized notes, chocolatey | Ice cream, compounds, cakes/muffins |

| Dark | Redwood, Sunfire, Bryce, Shenandoah, Cypress | Fudgy, rich alkalized notes | Brownies, cookies, icings |

| Darkest | Jet Black | Intensely alkalized | Cookies, coloring agent |

Alkalization Method: Due to the differences in processing, cocoas produced via these two methods perform differently in application.

- Cake alkalized cocoas have an inherent structure which may cause settling due to swelling of particles in water-based or beverage applications

- Nib Alkalization can reduce certain kinds of spore forming bacteria, and results in increased solubility as compared to cake alkalized cocoas. They may be more expensive but due to intense color, usage rate can be optimized in certain applications.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

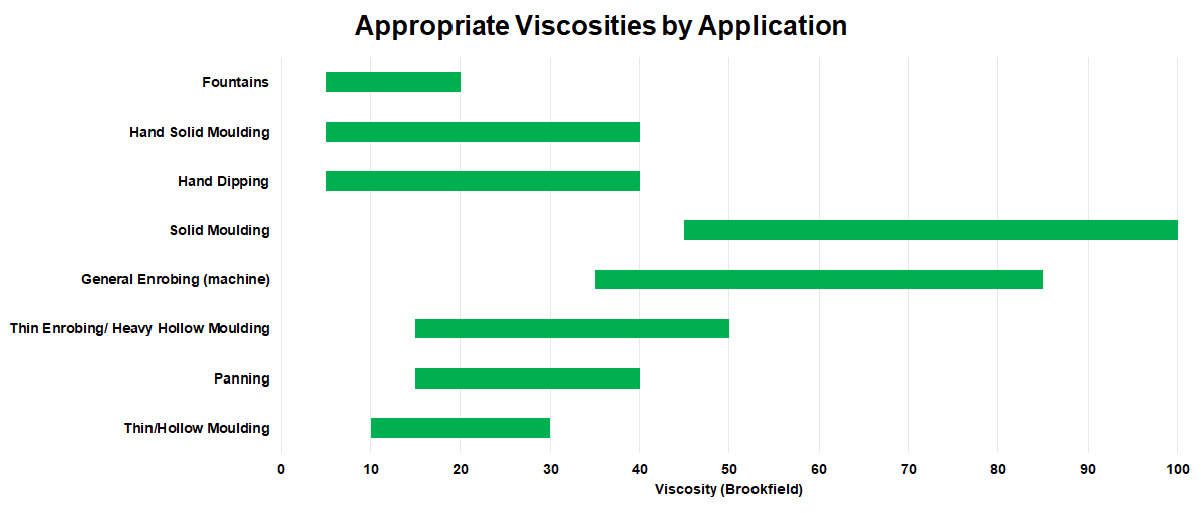

Viscosity is a measurement of a fluid’s resistance to flow. It is a quantity measuring the “internal” magnitude of friction between particles which are moving at different velocities. Viscosity is important because it affects how we utilize chocolate in a variety of applications, and the appropriate viscosity parameters yield ideal finished product appearance and quality. In general, lower viscosity samples are ideal for dipping or enrobing applications like a thin layer of coating covering a center. Higher viscosity chocolates and compounds are best suited but not limited to molded, panned, deposited or center applications where it is important for the product to have more coverage. In some applications like panning or depositing, the flow properties are used with equipment which helps form the finished product shape.

Viscosity can be characterized by three measurements: apparent viscosity, yield value, and plastic viscosity.

Apparent Viscosity

Apparent viscosity is a relative measurement used as a singular data point throughout the confectionery industry. Multiple measurements of apparent viscosities at different shear rates provide useful information about non-Newtonian fluids. For chocolates and compounds, the viscosity decreases when exposed to increased shear rates, this means that it is shear thinning therefore the viscosity decreases as the rate of shear increases.

The viscosity is measured at rotations per minute, and tested at industry standard temperatures, 40°C (104° F) for chocolate and 50°C (122° F) for compounds.

To get a more complete picture of the flow properties viscosity is measured at multiple shear speeds. This allows us to calculate the yield value and plastic viscosity.

Figure 1: Viscosity related to application usage in chocolate confectionery industry

Yield Value

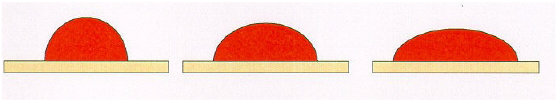

Yield value is the shear stress required to initiate flow of chocolate. Yield value affects the appearance of finished chocolate and compounds such as how a thin coating spreads, or how a thick product makes solid pieces like molded candies.

Impact on Chocolate: Higher yield value leads to a product which resists flow and would be ideal for a chocolate drop. A higher yield value will have a thicker viscosity which resists flow, producing a desired conical shape or a solid candy. A lower yield value coating will have a thinner viscosity that flows with little resistance like an ice cream coating.

Figure 2: A visualization of different relative levels of yield values from high (left) to low (right)

Plastic Viscosity

- Plastic viscosity is a function of the shear stress required to maintain constant flow.

- Plastic viscosity determines how well the chocolate will flow once it has started flowing.

Critical Parameters Which Impact Viscosity

- Temperature

- Melting point (of oils in sample)

- Temper state (over tempered vs. under tempered)

- Total fat

- Fat with unique crystallizing structures

- Particle size/distribution

- Degree of lecithination

- Moisture

- Heat Sensitive ingredients

- Emulsifier

Why Does Viscosity Matter for Chocolate Products?

The ideal viscosity range and flow parameters are imperative for every confectionery application to achieve the best quality and production performance. Once properly selected, viscosity impacts not only manufacturing and finished product appearance, but also most importantly our customers’ economic bottom line. Blommer strives to educate our customers about the viscosity of our chocolates and compounds in their applications so that they can produce superior confectionery candies for years to come.

Thanks for taking the time to learn a bit more about this topic. We love the ability to share some knowledge with you and we hope that you check out our other Technical Briefs. If you have any questions about this content, or about any Blommer products, please contact your local representative or call us at 1-800-825-8181.

As we all see on TV, trade publications and word of mouth yogurt is still very popular. We continue to see people trying to incorporate yogurt into just about everything including confections.

We offer a number of Yogurt Flavored Confectionery Coatings manufactured at three of our locations. Each formulation is developed for a specific application and flavor profile. Over the years our list of yogurt flavored coatings has increased based on trends and ingredient availability. We use various yogurt powders with each one having a different flavor profile and containing different ingredients such as cultured nonfat milk powder, whey protein concentrate, yogurt cultures, cultured whey and lactic acid.

The FDA has a standard of identity for yogurt (21 CFR 131.200, 203 or 206), but not one for yogurt powder. In general there are 2 types of yogurt powders. They include those that meet the standard of identity prior to drying and blended dairy mixes. The first group is made from yogurt, but requires a drying process to reduced moisture thus causing them to not contain live and active cultures and why they cannot be called yogurt. They do, however, contain other nutrients and the flavor of the yogurt. The second group is often just a mixture of milk ingredients to mimic the yogurt flavor.

Most recently the yogurt industry has been changed by the addition of Greek Yogurt. There is no current FDA regulation on what Greek Yogurt is, but it is characterized by a thick creamy yogurt with tart flavor and a higher level of protein. We can also provide Greek Yogurt Style Flavored Yogurt Coatings that have yogurt powders that mimic its flavor and nutritional profile or actual spray dried Greek Yogurt.

We recommend labeling products as Yogurt Flavored Confectionery Coating. Some will go as far as calling out that the yogurt is pasteurized after culturing or heat treated to further demonstrate that no live active cultures exist.

If you have additional questions, need additional technical support or would like a sample of Yogurt Flavored Coating please contact your sales representative or Technical Services at 1-800-621-1606.